Screwing in Lightbulbs, etc.

Wow, it keeps ratcheting up. Somehow we _thought_ the end would be kind of a tapering off, having (we thought) made "all" the important decisions. Ooof. We were wrong.

The end is is just crazy - tons of people, everywhere, every day - and decision after decision, minor crisis after minor crisis. It's exciting, and fun, but we are definitely getting tired.

I can't even list the number of things happening right now, but here's a smattering:

Pulls - remember all those cabinets we agonized over - layout, wood, heights, etc.? Well, it turns out that they all need some sort of pull or handle. There are only about 85,000 to choose from. Oh, and not only do you have to figure out what pulls to use, you then have to figure out WHERE to actually put them. Did I mention that you can't really get it wrong as they'll be drilling holes in the face of every cabinet door and drawer front so there's no going back?

Here are some (a small fraction, this is just from one box of samples) that we've looked at for the master bathroom and bedroom:

The kitchen is even more fun - we've known we've wanted "European stainless steel bar pulls" for a while, so that narrowed down the search to only about 300 options, many of which were variations of this basic look:

We finally found a somewhat unique design from Siro that we really liked as it had the "rectangular" theme that's emerged everywhere in the house:

So, done, right? Um. Not even close.

[OCD Alert] OK, so how do you reconcile that the pulls only come in 4 lengths but the drawers and doors come in about 15 different lengths? Use the same one everywhere you say? OK, that works on the cabinet doors, but a small pull on giant drawer front, I think not. OK, use the different size ones, then match them up as best you can? Maybe, but still unsatisfying.

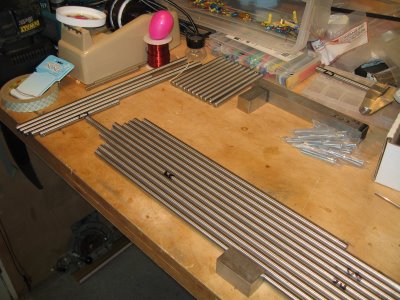

Then factor in that there's a Bridgeport milling machine and a Hardinge lathe in the garage...and the answer, naturally, is, make them all precision custom lengths to match all the fronts:

After a few late nights, I've finished the cabinet ones - 15 were totally standard, 24 were custom in some way. I'm still making the last 3 larger ones for the refrigerator. The custom lengths will enable us to maintain the same "edge distance" on all the fronts - so that the mounting blocks are all set in the same distance from the vertical edge of the face.

The cabinet guys haven't mounted any as yet, so we'll let you know how well this plan worked out in a later post.

And, while on the topic of custom fabrication, here's the Teak shower floor in process. Cathy helped rout the edges and sand all the pieces.

I bought World's Most Terrifying Woodworking Tool ® off Craigslist - an ancient Rockwell Jointer - for $40 - to joint all the boards. You just had to ignore the fact that cutter guard was missing, the cord was disintegrating, and the v-belt drive didn't have (and never had) a guard. It actually worked great, the cutterhead was even sharp. I'll buy a better one someday, but this was a quick solution.

The deck came out great, but I don't have a picture of it installed yet as the stairs have been getting finished so I can't actually get up to the bathroom. The whole staircase is looking really, really awesome! The floating platform at the bottom is killer cool:

It's exactly what we were picturing, but even better.

Ken the electricain continues to trim out all the fixtures, switches, outlets, etc. Here is is working on the exercise room light trim - he has to cut out the gypboard for the fixture, hence the coating of plaster dust:

Speaking of messes, here's the driveway approach being torn up. The city is making us replace the cracked sections of the driveway and the sidewalk.

The crew set a new record - they had busted through the watermain by 8:12am (their day starts at 8am). Note the flood on the sidewalk, and the guy in the red shirt trying to turn off the main.

Quick quiz: find the company owner in the picture below:

There was a giant cloud of concrete dust as they saw cut the old sidewalk (extra credit: find the owner again):

Our master balcony railing also arrived, some assembly required. Hopefully they will be back this week to do the install. That's the easy one. The stair rail is the last major challenge, hopefully we'll see that next week. That's the last substantial piece of the puzzle we absolutely need before final inspection, which I think Fred is trying to get around July 1.

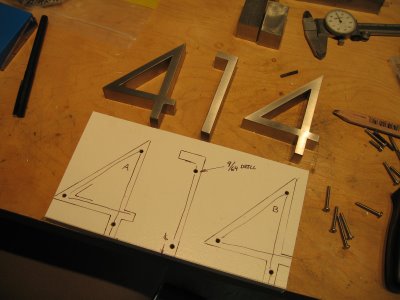

Oh, and one more piece of OCD - I'm making a drill template for the house numbers so as to get the alignment and kerning just so.

Hey, we've come this far...

The end is is just crazy - tons of people, everywhere, every day - and decision after decision, minor crisis after minor crisis. It's exciting, and fun, but we are definitely getting tired.

I can't even list the number of things happening right now, but here's a smattering:

Pulls - remember all those cabinets we agonized over - layout, wood, heights, etc.? Well, it turns out that they all need some sort of pull or handle. There are only about 85,000 to choose from. Oh, and not only do you have to figure out what pulls to use, you then have to figure out WHERE to actually put them. Did I mention that you can't really get it wrong as they'll be drilling holes in the face of every cabinet door and drawer front so there's no going back?

Here are some (a small fraction, this is just from one box of samples) that we've looked at for the master bathroom and bedroom:

The kitchen is even more fun - we've known we've wanted "European stainless steel bar pulls" for a while, so that narrowed down the search to only about 300 options, many of which were variations of this basic look:

We finally found a somewhat unique design from Siro that we really liked as it had the "rectangular" theme that's emerged everywhere in the house:

So, done, right? Um. Not even close.

[OCD Alert] OK, so how do you reconcile that the pulls only come in 4 lengths but the drawers and doors come in about 15 different lengths? Use the same one everywhere you say? OK, that works on the cabinet doors, but a small pull on giant drawer front, I think not. OK, use the different size ones, then match them up as best you can? Maybe, but still unsatisfying.

Then factor in that there's a Bridgeport milling machine and a Hardinge lathe in the garage...and the answer, naturally, is, make them all precision custom lengths to match all the fronts:

After a few late nights, I've finished the cabinet ones - 15 were totally standard, 24 were custom in some way. I'm still making the last 3 larger ones for the refrigerator. The custom lengths will enable us to maintain the same "edge distance" on all the fronts - so that the mounting blocks are all set in the same distance from the vertical edge of the face.

The cabinet guys haven't mounted any as yet, so we'll let you know how well this plan worked out in a later post.

And, while on the topic of custom fabrication, here's the Teak shower floor in process. Cathy helped rout the edges and sand all the pieces.

I bought World's Most Terrifying Woodworking Tool ® off Craigslist - an ancient Rockwell Jointer - for $40 - to joint all the boards. You just had to ignore the fact that cutter guard was missing, the cord was disintegrating, and the v-belt drive didn't have (and never had) a guard. It actually worked great, the cutterhead was even sharp. I'll buy a better one someday, but this was a quick solution.

The deck came out great, but I don't have a picture of it installed yet as the stairs have been getting finished so I can't actually get up to the bathroom. The whole staircase is looking really, really awesome! The floating platform at the bottom is killer cool:

It's exactly what we were picturing, but even better.

Ken the electricain continues to trim out all the fixtures, switches, outlets, etc. Here is is working on the exercise room light trim - he has to cut out the gypboard for the fixture, hence the coating of plaster dust:

Speaking of messes, here's the driveway approach being torn up. The city is making us replace the cracked sections of the driveway and the sidewalk.

The crew set a new record - they had busted through the watermain by 8:12am (their day starts at 8am). Note the flood on the sidewalk, and the guy in the red shirt trying to turn off the main.

Quick quiz: find the company owner in the picture below:

There was a giant cloud of concrete dust as they saw cut the old sidewalk (extra credit: find the owner again):

Our master balcony railing also arrived, some assembly required. Hopefully they will be back this week to do the install. That's the easy one. The stair rail is the last major challenge, hopefully we'll see that next week. That's the last substantial piece of the puzzle we absolutely need before final inspection, which I think Fred is trying to get around July 1.

Oh, and one more piece of OCD - I'm making a drill template for the house numbers so as to get the alignment and kerning just so.

Hey, we've come this far...

0 Comments:

Post a Comment

<< Home